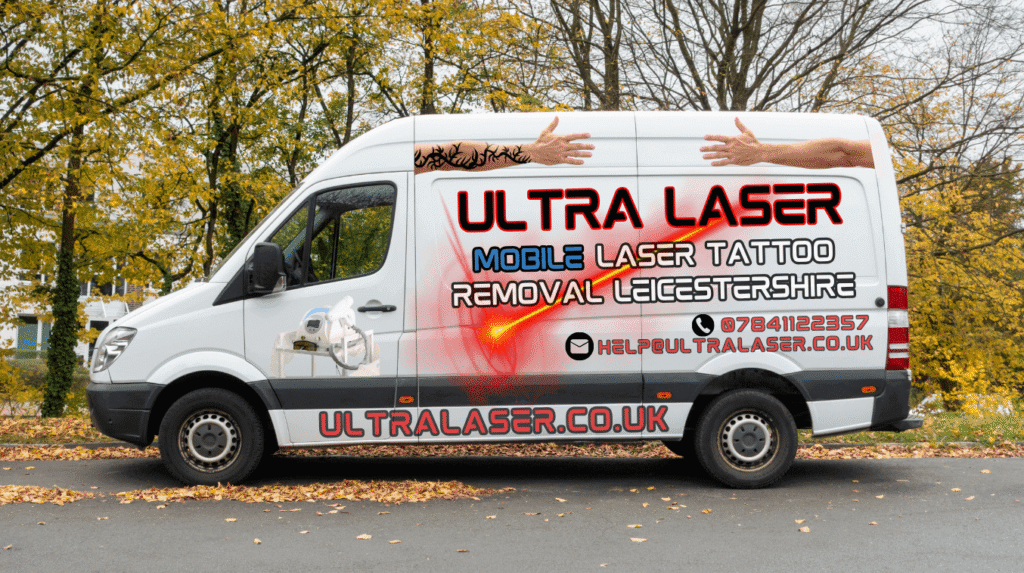

MOBILE TATTOO REMOVAL

Mobile Laser Tattoo Removal Leicester

My flexible mobile laser tattoo removal service offers safe, professional, and effective tattoo removal in the comfort of your own home. Using advanced laser technology, I target unwanted ink with precision while prioritising your comfort and skin health. Whether you’re looking to fade a tattoo for a cover-up or remove it completely, I provide a discreet, fully insured service designed around your schedule. No clinics, no waiting rooms—just reliable results brought directly to you.

At Ultra Laser Mobile Tattoo Removal Leicestershire, I proudly offer professional mobile laser tattoo removal and carbon face peel treatments and services across a wide area surrounding South Leicestershire. My flexible service brings advanced ND YAG laser technology directly to your home, providing convenience, discretion, and expert care without the stress of travelling to a clinic. I cover all surrounding towns and villages within an approximate 12-mile radius, including Hinckley, Earl Shilton, Barwell, Sapcote, Sharnford, Broughton Astley, Croft, Desford, and Ullesthorpe. I also regularly visit larger nearby towns such as Lutterworth, Nuneaton, Enderby, Blaby, and Countesthorpe, as well as parts of Leicester, Tamworth , Lichfield, Sutton Coldfield, Staffordshire and Coventry Warwickshire and its surrounding suburbs.

Whether you’re in a quiet village or a busier town, I bring a clean, comfortable, and fully insured service right to your door. With mobile appointments tailored to suit your lifestyle, you can begin or continue your tattoo removal journey in the comfort of your own space. If you live in or around any of these areas and are interested in laser tattoo removal, feel free to get in touch — I’ll be happy to confirm if I can come to you.

More Info

- The Process: Simply contact me here with a photo of your tattoo and your location.

- Easy Booking: No broken booking systems here! simply message me on WhatsApp for a quote and to book in your mobile laser removal at a time and location that suits you!

- Secure Payment: Due to the nature of my mobile tattoo removal service, please note that a 50% deposit is required when booking your Consultation, Patch Test & Laser Treatments.

8+

Years in the business

247+

HAPPY CLIENTS

Ultra Laser Mobile Tattoo Removal Leicestershire – 5 Star Reviews

Here at Ultra Laser Mobile Tattoo Removal Leicestershire, I am proud of my 5 Star Customer Feedback, Click Here to See More Reviews

Why use Ultra Laser Mobile Tattoo Removal Leicester?

If you’re looking for a convenient, professional, and results-driven way to remove unwanted tattoos, my mobile laser tattoo removal Leicester is the ideal choice. I bring the treatment directly to you, eliminating the need for travel, parking, or waiting rooms. Whether you’re at home or another private location, I create a safe and comfortable environment for each session. This flexible approach is perfect for busy lifestyles and those who value privacy during the removal process.

With over 8 years of experience in the tattoo removal industry, I’ve helped hundreds of clients achieve their skin goals. I use state-of-the-art ND YAG laser technology — known for its effectiveness on a wide range of ink colours and skin types — along with professional-grade skin cooling systems to minimise discomfort and protect your skin during each session. Every treatment is tailored to your tattoo’s size, location, colour, and depth, ensuring the best possible outcome while prioritising skin safety.

Based in South Leicestershire, I offer mobile appointments throughout the region, bringing expert-level tattoo removal to your doorstep. As a fully insured and highly experienced technician, I focus on delivering consistent results with a personal, one-on-one approach you won’t find in high-street clinics. Whether you’re planning a cover-up or want a clean slate, I’m here to help you every step of the way — with no travel hassle, no clinic stress, just honest, effective results.

Mobile Laser Tattoo Removal Leicester Prices Start From Just £75 Per Session!

Convenience & Comfort

- Treatment in the comfort of your own home

- No travel, parking, or waiting rooms

- Flexible appointment times to suit your schedule

- Discreet, private sessions

- Ideal for people with mobility or time constraints

- One-on-one focused service without clinic distractions

- No need to book time off work or arrange childcare

- Calmer environment = less anxiety for first-timers

- Sessions can be done in a relaxed, familiar space

- South Leicestershire local service — fast and reliable arrival

Expertise & Experience

- 8+ years of tattoo removal experience

- Skilled in treating a variety of ink types and skin tones

- Professional advice on fading vs full removal

- Clear aftercare guidance for best healing

- Honest consultations — no pressure sales

- Hundreds of successful removals completed

- Experience with all body areas and tattoo sizes

- Realistic expectations and personalised treatment plans

- Specialist in preparing tattoos for cover-ups

- Fully insured and qualified technician

Advanced Technology & Safety

- Advanced ND YAG laser system used for deep and effective results

- Effective on black, coloured, and layered inks

- Using a 1064nm and 532nm Laser Wavelengths, most colours can be removed

- Professional skin cooling device reduces discomfort

- Precise laser targeting to protect surrounding skin

- Modern equipment maintained to high clinical standards

- Regularly updated techniques and safety protocols

- No harsh chemicals — laser only

- Non-invasive and non-surgical

- Strict hygiene practices during every session

- Treatment tailored specifically to your skin and tattoo

- Aftercare advice and creams offered

How Does Laser Tattoo Removal Work?

Mobile Laser Tattoo Removal Leicester :- Laser tattoo removal with an ND:YAG laser is a safe, effective, and non-invasive method for gradually fading or completely removing unwanted tattoos. The process works by directing short pulses of high-intensity light into the skin, where the tattoo ink particles absorb the energy. This causes the ink to shatter into smaller fragments, which are then naturally flushed out by the body’s immune system over the following weeks.

The ND:YAG laser (short for Neodymium-doped Yttrium Aluminum Garnet) is widely regarded as one of the most effective technologies for tattoo removal, especially for darker ink colours like black and deep blue. It can also be adjusted to target other colours such as red, green, or orange using different wavelengths. One of the key benefits of ND:YAG lasers is their ability to penetrate deep into the skin without damaging the surrounding tissue, making the process both safe and precise.

Treatments are typically spaced 6 to 8 weeks apart, giving the skin time to heal and the body time to process the fragmented ink. Multiple sessions are usually required, depending on the tattoo’s size, location, ink colour, age, and depth. During each session, a skin cooling system is used alongside the laser to reduce discomfort and protect the surface of the skin, helping to make the experience more comfortable for the client. With proper aftercare and professional handling, ND:YAG laser tattoo removal is a trusted method for those looking to fade, change, or fully remove unwanted tattoos.

Call Matt at Ultra Laser Tattoo Removal Today!

Although Ultra Laser Mobile Tattoo Removals cover the South Leicestershire area, I am happy to travel further if required. Please do not hesitate to get in touch for your free quote today!